Mercedes aluminum welding is a specialized technique for collision repair and bodywork restoration, fusing lightweight yet robust aluminum panels to ensure structural integrity and aesthetic appeal of Mercedes vehicles, adhering to original manufacturer standards. Skilled technicians use advanced equipment and knowledge to perform precise welds, crucial for safety, reliability, and preserving the sleek design and high-quality construction of Mercedes cars.

Mercedes aluminum welding is a precision art crucial for repairing impact zones and strengthening load paths in vehicle chassis. This advanced technique, specialized for Mercedes vehicles, ensures structural integrity and longevity by seamlessly integrating replacement parts with the original body. By understanding the unique weld types and their applications, technicians can precisely replicate the manufacturer’s design, maintaining both performance and safety standards. From crumple zones to support beams, effective Mercedes aluminum welding is vital for optimal vehicle repair.

- Understanding Mercedes Aluminum Welding Techniques

- Impact Zones: Where Precision Matters Most

- Load Path Repairs: Strengthening the Chassis through Welding

Understanding Mercedes Aluminum Welding Techniques

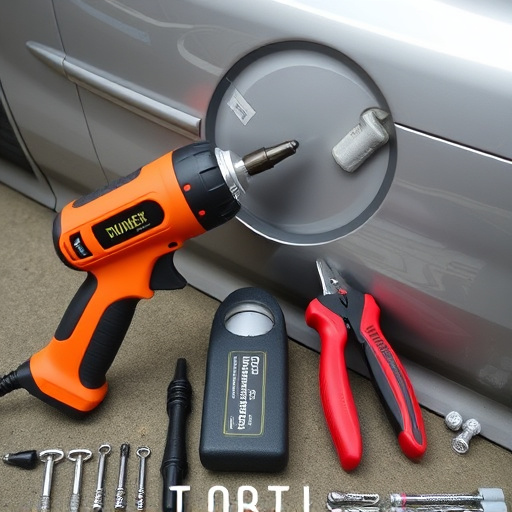

Mercedes aluminum welding is a specialized technique that plays a critical role in collision repair and car bodywork restoration. This process involves fusing aluminum panels together to create strong, durable bonds, which are essential for repairing impact zones and load paths on Mercedes vehicles. The techniques employed by professionals ensure that these repairs match the original manufacturer standards, maintaining the vehicle’s structural integrity and aesthetic appeal.

Aluminum is a lightweight yet robust metal, making it popular in modern car design, especially in high-performance models. When damage occurs to a car’s body—whether from an accident or wear and tear—Mercedes aluminum welding offers a precise and effective solution. Skilled technicians use specialized equipment and knowledge of the material’s properties to create seamless welds, restoring the car to its pre-damage condition. This advanced welding method is key to ensuring the safety and reliability of Mercedes vehicles after collision repair or car damage repair processes.

Impact Zones: Where Precision Matters Most

Impact zones on a vehicle are areas that bear the brunt of collisions or accidents, and their structural integrity is vital for passenger safety. When it comes to repairing these critical segments, Mercedes aluminum welding stands out as a game-changer. This advanced technique offers unparalleled precision, ensuring every weld is precisely positioned and aligned, which is crucial for maintaining the vehicle’s structural integrity and performance.

Mercedes vehicles are renowned for their sleek designs and high-quality construction, and aluminum is a key component in achieving these aesthetics. When carrying out car dent removal or auto maintenance on impact zones, using Mercedes aluminum welding techniques allows technicians to restore the original strength and beauty of the vehicle while adhering to stringent safety standards. This meticulous approach is essential for drivers’ peace of mind, knowing their vehicle’s repair has been executed with the utmost care and attention to detail.

Load Path Repairs: Strengthening the Chassis through Welding

In the intricate world of luxury vehicle repair, particularly for iconic brands like Mercedes, Load Path Repairs play a pivotal role in enhancing safety and structural integrity. These repairs focus on fortifying the chassis, a critical component that forms the load path during driving. By utilizing specialized Mercedes aluminum welding techniques, technicians can effectively strengthen and reunite components affected by impact zones, ensuring the vehicle’s overall stability and performance.

Aluminum welding offers several advantages for this specific type of repair. It facilitates precise alignment and seamless integration of parts, which is especially crucial in preserving the vehicle’s original structural integrity. Moreover, aluminum welding techniques allow for minimal disruption to the surrounding areas, enabling more intricate and meticulous repairs without compromising the overall aesthetics of the luxury vehicle. This precision is particularly valuable when addressing complex impact zones, ensuring that the Mercedes retains its elegance and value even after undergoing significant car restoration efforts.

Mercedes aluminum welding is a precision art vital for repairing impact zones and load paths in vehicles, ensuring structural integrity and optimal performance. By understanding advanced welding techniques specific to Mercedes models, technicians can expertly strengthen chassis components, enhancing safety and vehicle longevity. This specialized process, focused on critical areas, underscores the importance of high-quality welding in modern automotive repairs.